Há pouco menos de duas décadas, a blindagem era feita apenas com peças rígidas e seu processo de modelagem impossibilitava atender uma gama diversificada de veículos. Porém, a BCA BALLISTIC PROTECTION, com a reconhecida capacidade de pesquisa e desenvolvimento tecnológico, começa a reescrever a história da linha de painéis balísticos.

O NeoFlex® Tape foi lançado em 2015 na Milipol Paris - a principal feira internacional de Segurança e Defesa e foi considerado um dos lançamentos tecnológicos de maior impacto na indústria de proteção balística internacional.

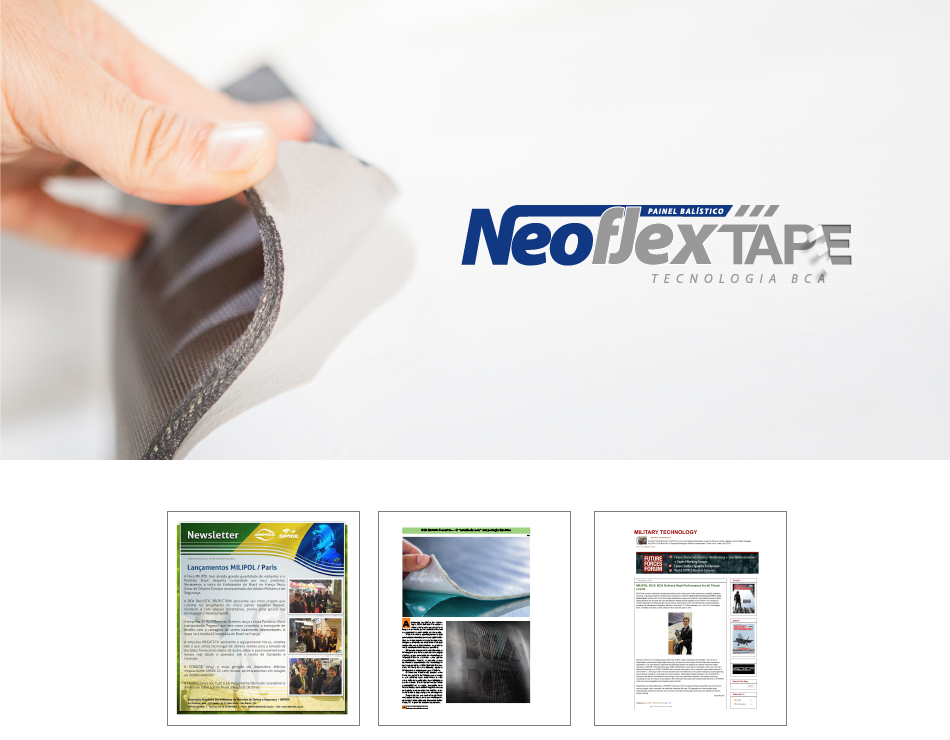

A tecnologia NeoFlex® Tape é a única que permite a moldabilidade e a colagem instantânea, por ser a única autoadesiva do mercado. Mantendo como característica a proteção balística de alto desempenho que os painéis BCA oferecem, e até 25% mais leves, a tecnologia Neoflex Tape® garante otimização e minimiza possíveis erros no processo de aplicação.